We Focus on Gas Engine Spare Parts

Challenges When Obtaining Spare Parts

In the current gas engine spare parts market, we may encounter several challenges such as difficulties in obtaining quotes from suppliers, long lead times, extended supply cycles for OEM parts, inconsistent quality of non-genuine parts and high minimum order quantities (MOQ) for OEM components resulting in a lack of cost-effectiveness in spare parts procurement.

Genuine Part ETA so Long

Genuine parts are typically our first choice. However, in many cases, production capacity constraints at the genuine parts manufacturer may result in longer estimated time of arrival (ETA) for our orders. This is because genuine parts manufacturers often prioritize orders from major customers or distributors, leading to longer ETAs for smaller clients.

Non Genuine Parts Quality unpredictable

Most non-genuine parts manufacturers rely on their own understanding of the components to manufacture or select from their supply chain. However, deviations in their understanding of the intended use of the spare parts can lead to discrepancies in material and process selection during manufacturing, resulting in unpredictable quality control issues.

MOQ for Genuine & OEM Parts

Sometimes, we can find suitable genuine parts or OEM parts suppliers. However, these suppliers can offer us a competitive price only if we meet their minimum order quantity (MOQ).

Manufacture Material Plan

Some engine manufacturers offer material plans to customers to obtain better ETAs and prices. However, these plans often cater to customers with significant equipment volumes, making them less favorable for smaller clients with lower quantities.

Solution

In response to these challenges, we've implemented several solutions. We offer a self-service quoting system for instant quotes. Our technical experts thoroughly evaluate selected products for reliability. We've developed a Ping-go system to meet suppliers' MOQ requirements and optimize cost-effectiveness. Plus, we maintain stock of commonly used spare parts to improve supply ETAs.

Self-service quote system

Our self-service quote service significantly saves on communication costs and improves efficiency between our clients and us.

OEM Ping-Go

Through our ping-go system, we can solve the MOQ issue requested by suppliers for high-value OEM products for our customers, while our customers can also resolve their excess inventory through our Ping-go system.

Global Experts verification

We invite experts from around the world to participate in our ARI evaluations, ultimately determining whether we develop corresponding replacement parts products. This fundamentally addresses the quality issues with our replacement parts products.

Always Stock On Common Parts

We utilize big data analysis of past inquiries and order quantities to ensure, to the best of our ability, that commonly used spare parts are kept in constant stock.

Why Us?

In a market crowded with biogas engine suppliers, why choose us? We stand out by leveraging advanced information systems to enhance efficiency, allowing us to focus more on product alternatives. Our expert technical forum ensures better understanding and quality control. Through our Ping-go system, we charge minimal organizational fees, passing on most of the benefits to our customers. We also use big data sales predictions to ensure stock availability, optimizing ETAs.

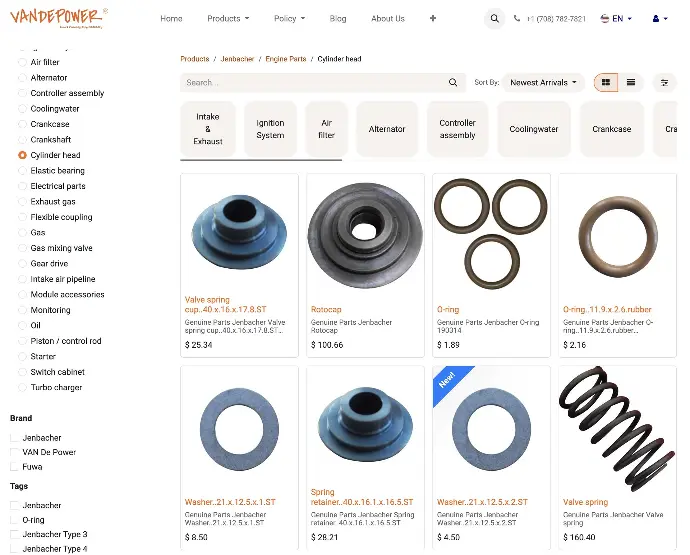

Products

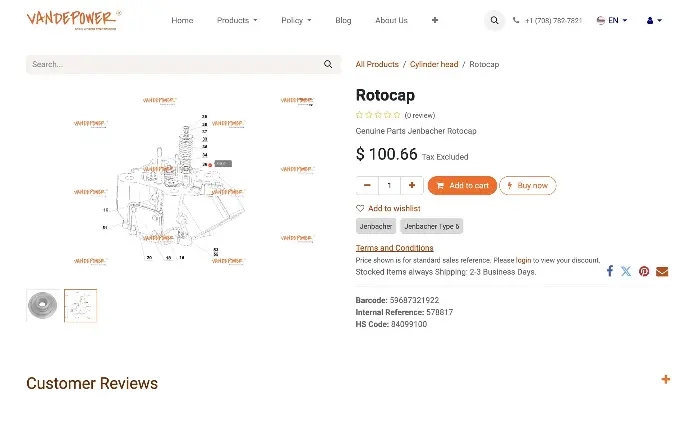

ARI Evaluation, Customer Joined Roadmap, Stock

All Selected Product Evaluated by Experts

Our replacement parts products are evaluated by selected technical experts chosen by us, who deem them suitable for substitution.

Clearly Products Development Roadmap

Our product development roadmap will be listed on our website, and you can also participate in shaping our product and service development roadmap. Through our review process, we will prioritize your product and service needs to enhance our service efficiency and meet your service requirements.

Always stock on 1300+ Products

We will maintain a stock of over 1300 items in our warehouse to meet your common stock needs at any time.

Service

Efficiency, Certainly, Reliability

Efficiency

Our core mission is to provide you with dependable, reliable, and efficient service. You can quickly access the information you need through our web chat and receive prompt responses. We have colleagues in Southeast Asia, China, and South America ready to address any of your needs.

Certainly

We will track all our operations through barcodes, allowing you to conveniently trace the status of your orders throughout the entire process of inquiry, ordering, and receipt. In short, our goal is to provide customers with a visual and deterministic service process.

Reliability

We evaluate our replacement parts products through the ARI system, track the entire service process through information systems, and use Product Recall to enhance our after-sales service. This enables us to provide reliable products and services to our customers.

How We do?

To implement the aforementioned solutions, we first developed a self-service quoting system to greatly enhance quote efficiency for customers, thereby reducing our maintenance costs and ultimately passing on the savings to them. With the development of our Ping-go system, customers can obtain the best value for Genuine and OEM Parts. Our integrated system allows customers to complete all steps from quoting, ordering, payment, contract signing, customer service, to shipping on a single platform, enabling real-time tracking at every stage. Through our ARI evaluation, we ensure that every product we select meets production and process requirements.

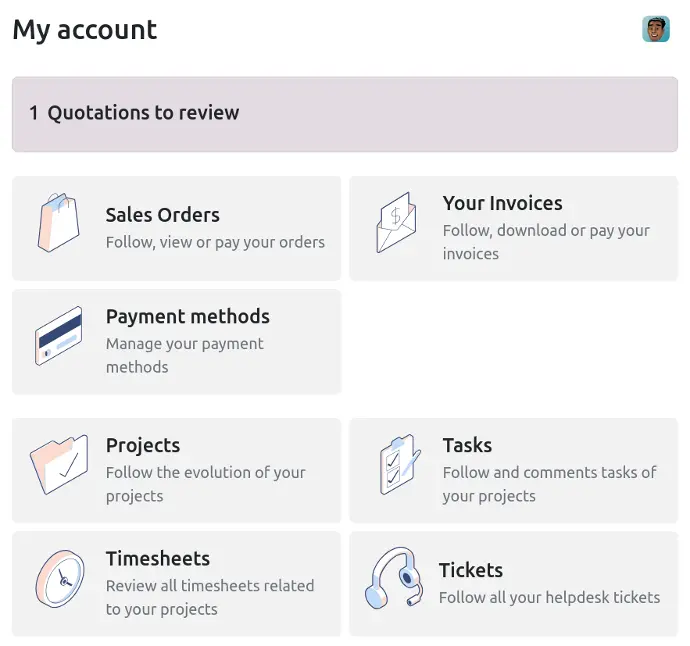

Self-service Quote & Order

Based on our past experience, the conversion rate from quote requests to finalized orders among our customers is approximately 8-10%. To handle these quotes, we need to allocate resources to process a significant number of these inquiries, many of which may not lead to orders. Therefore, we have opened up our pricing system, allowing customers to generate quotes themselves at any time. This initiative is expected to save us around 11-19% in operating costs annually. We can then pass these cost savings on to our customers.

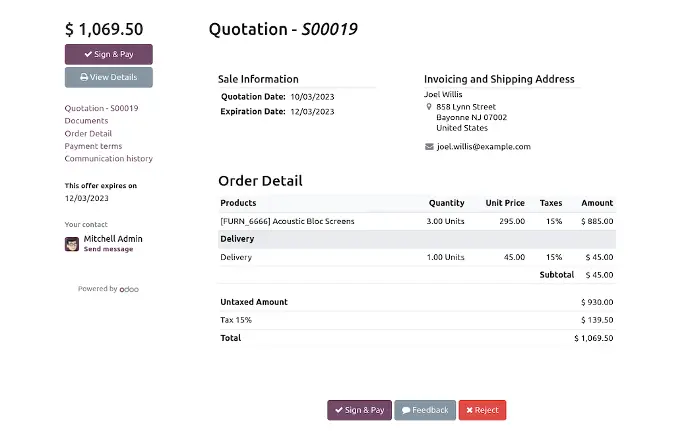

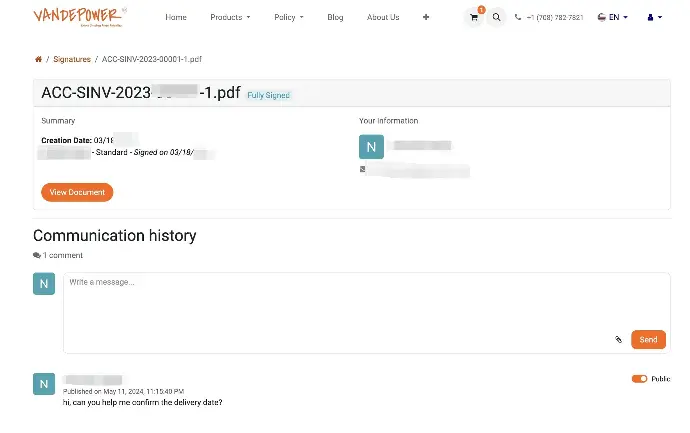

Procedure Trackable

Many customers, while working with other suppliers, often need to inquire about the progress of their orders to stay informed about their status. Our system addresses this by providing real-time updates to customers via email, SMS, and system notifications, informing them about the current status of their orders. On each order page, customers can freely comment on their questions and requirements. They can also sign contracts online, make payments online, and even view images or videos of their orders being picked and packaged in our warehouse. This ensures that every step of the customer's order is trackable in real-time.

ARI Evaluation

When selecting alternative parts, many times customers encounter substitutes that should not be used in place of original parts because the failure of these substitutes can sometimes result in costs far exceeding the procurement savings gained from using them. To address this, we utilize our network technology forum's technical experts to conduct ARI (Alternative Replacement Index) assessments on replacement parts we plan to develop. Only when the ARI meets the required evaluation criteria do we proceed with the development of the replacement part.

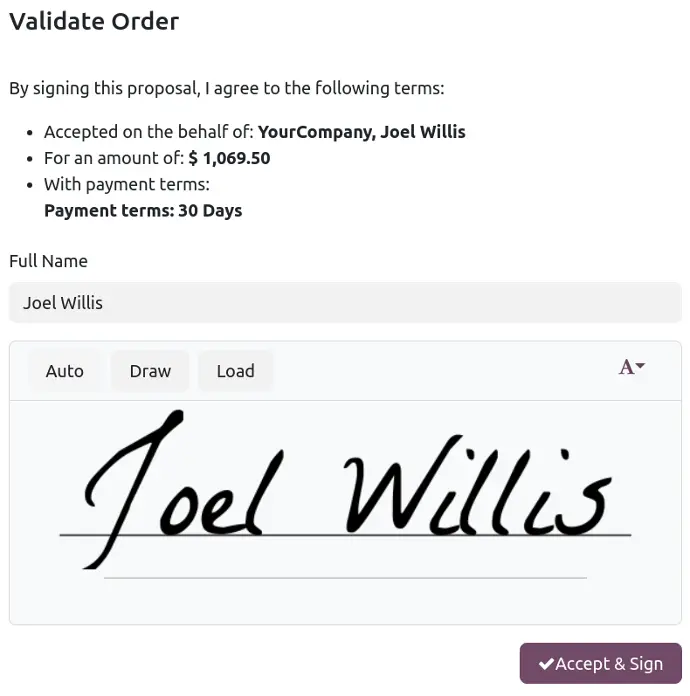

Online Payment & Contract Signature

Our customers can use our online payment system to pay for small orders using credit cards. We also offer account payment services in multiple currencies. Additionally, we provide cryptocurrency payment options to facilitate the use of the most optimal and cost-effective payment methods. Our customers can also sign contracts online and download or view them using our online contract management system.

1300+ Common Used Part Always Stock

We have analyzed data from previous periods and identified over 1300 commonly used spare parts for various equipment models. Utilizing big data analysis of past orders and inquiries, we forecast future demand to ensure optimal warehouse stock levels. This greatly enhances our order ETAs.

Ping-go System

Through our Ping-go system, we first identify suitable suppliers and products, determine the MOQ, and then publish and notify all potential customers who may purchase the product. Customers only need to pay 10% of the total demand amount to reserve the item. Once the total demand quantity reaches the MOQ, our Ping-go is successful, and all reserved customers are notified to pay the remaining balance and arrange for delivery. If the total demand quantity does not meet the MOQ, we will fully refund the customers. We will publish all supplier and product pricing information on the Ping-go system, and based on the quotes, we only charge a 3-3.5% service fee.

All brand logos and names appearing on this website, including Jenbacher, INNIO, GE, GAUSCOR, DUNGS, Woodward, Mann Hummel, ABB, Heinzmann, and B&R etc., are the property of their respective companies and are used for reference purposes only for product part numbering. The use of brand logos and names does not imply ownership or authorization by us. Their use does not indicate any form of endorsement or affiliation with these brands. All trademarks and logos belong to their respective companies.